|

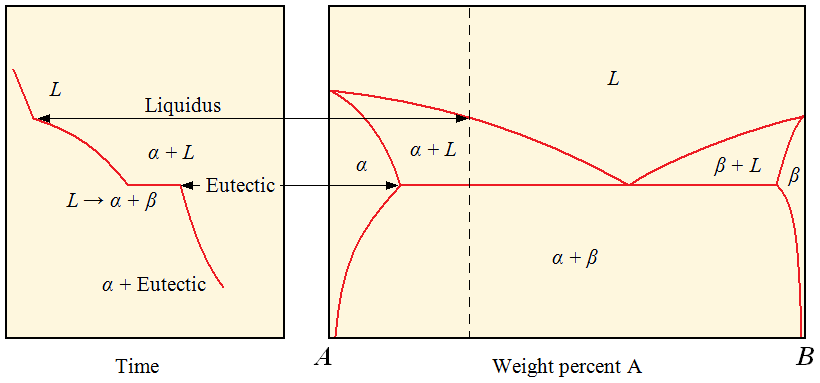

The figure shows a eutectic binary phase diagram to the right, and its corresponding cooling curve for the specific composition indicated by the dashed line in the eutectic diagram. There is a corresponding cooling curve for any composition in the eutectic phase diagram. The cooling curve for a hypoeutectic alloy is a composite of those for solid solution alloys and "straight" eutectic alloys. A change in slope occurs at the liquidus as primary α begins to form. Evolution of the latent heat of fusion slows the cooling rate as the solid α grows. When the alloy cools to the eutectic temperature, a thermal arrest is produced as the eutectic reaction proceeds. The solidification sequence is similar in a hypereutectic alloy.

|