| Fracture Toughness |

| Stress intensity factor |

| K | stress intensity factor |

| f | geometry factor for the specimen and flaw |

| σ | applied stress |

| a | flaw size |

| Kc | fracture toughness |

| KIc | plain strain fracture toughness |

|  |

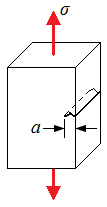

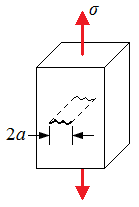

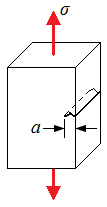

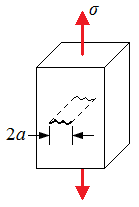

| edge flaw | internal flaw |

| (Eq1) |

|

| ksi√ | in. | = 1.0989 MPa√ | m |