| Good | Poor | The matrix should be soft and ductile, although the precipitate should be strong. The precipitate interferes with slip, while the matrix provides at least some ductility to the overall alloy. |

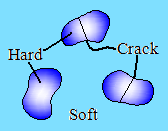

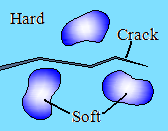

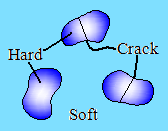

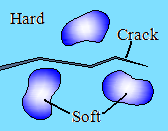

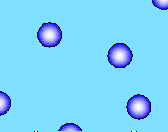

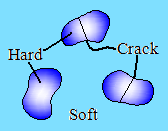

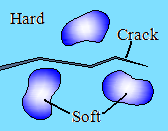

|  | The hard precipitate should be discontinuous, while the soft, ductile matrix should be continuous. If the precipitate were continuous, cracks could propagate through the entire structure. However, cracks in the discontinuous, brittle precipitate are arrested by the precipitate-matrix interface. |

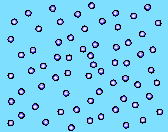

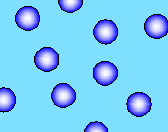

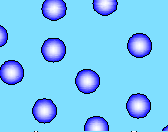

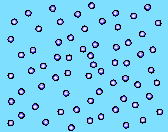

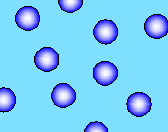

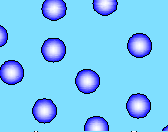

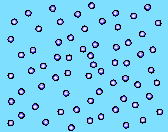

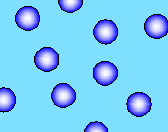

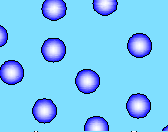

|  | Precipitate particles should be small and numerous, increasing the likelihood that they interfere with the slip process. |

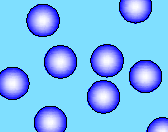

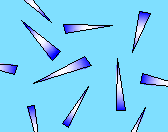

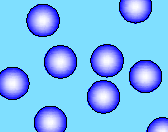

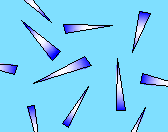

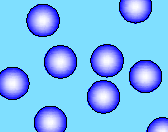

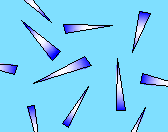

|  | Precipitate particles should be round, rather than needlelike or sharp-edged, because the rounded shape is less likely to initiate a crack or to act as a notch. |

|  | Large amounts of precipitate increase the strength of the alloy. |