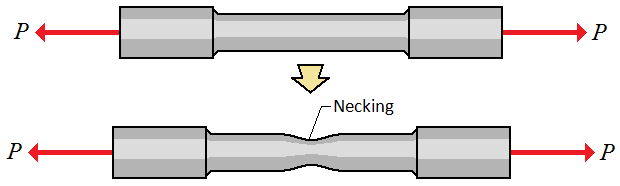

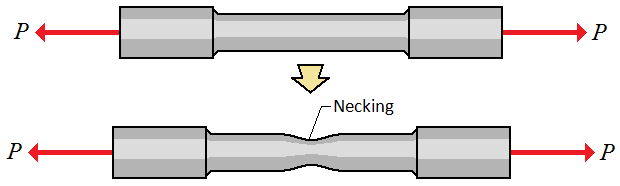

The above image shows a test specimen, when of a certain kind of material, and experienced under a great enough load, experiences necking.

The portion where necking occurs may be called the neck of the specimen.

| Necking |

The above image shows a test specimen, when of a certain kind of material, and experienced under a great enough load, experiences necking. The portion where necking occurs may be called the neck of the specimen. |

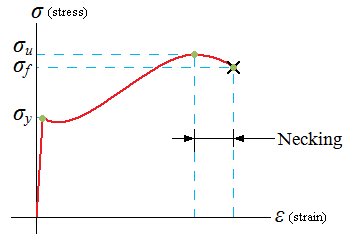

The above figure shows the necking region in a stress-strain diagram for a ductile material. |

| ⇐Previous Lesson: Offset Yield Method | Next Lesson: True Stress, True Strain, Engineering Stress, and Engineering Strain⇒ |